µPD765A Disc Controller – Primer

Back in the 80’s, Disk protection systems were starting to evolve at a rapid rate, presumably due to the use of IBM PC’s, Amiga/Atari STs on the market that could do a lot more with the controller than had been implemented on the target hardware. These machines were beasts in comparison, having more memory and could cross compile to multiple target machines with ease, making development of games and tools more efficient and streamlined. The PDS (Programmers Development System) was an expensive bit of kit, way out of my price range (Starting at around £2K). https://retro-hardware.com/2019/05/29/programmers-development-system-pds-by-andy-glaister/

Whilst using documented and undocumented AMSDOS ROM commands got you so far, understanding and fully controlling the µPD765A controller became necessary.

A friend back then “Dave” had access to all sorts of hardware documentation. One morning on his way to work, he dropped off a bundle of documents including hardware/circuit diagrams for the Amstrad CPC computer range, service documents and the µPD765A specification. Stuff I couldn’t get hold of myself.

I set to work reading the documentation, learning about Microelectronics at school helped enormously. From about the age 10, I was no stranger to a soldering iron and PCBs. The article below is the result of my own work back in the late 80s, using code from my original three inch disks. This will serve as a simple primer before I write up how I went about developing hacks for old school disk protections systems, some fo which went into commercial tools with Goldmark’s Nirvana+ and Nemesis Bonzo Pack for Sector #48, 6K Sectors and more.

Please Note

This article is a Primer only, to cover the basics. I will be following up with write ups of other FDC Commands such as Track Read which I took advantage of to create a Disk Protection System JaceLock, and more.

My Git Hub Repo containing my legacy disks and source code (Still to be sorted), is found here: https://github.com/muckypaws/AmstradCPC

The source code for this write up can be found: –https://github.com/muckypaws/AmstradCPC/blob/master/Assembly/DDFDC/DDFDC_MK2.asm

Thank you for taking the time to read my Blog.

If you would like to support me and my work, please check out my Online Store: www.muckypawslabs.com alternatively…

We all know developers and coders run on Coffee…

Choose an amount

Your contribution is appreciated.

DonateWhat do you need?

The article is technical in nature, and may be rough on the novice or beginner starting out to understand the history behind this… That said, you’re here so, please stick with it, it will make sense (Eventually), and I’m not the best at explaining tech stuff in layman terms, therefore constructive feedback is always welcome, or share your own experiences when coding for this tech. We all approach problems from differing angles.

- You’ll need some Z80 Assembler Knowledge and Skills.

- A development Environment

- I use ADAM IDE for the Amstrad CPC, though JavaCPC contains a built in developer environment for assembly and disassembly to practice.

- The µPD765A Specification.

AMSDOS ROM

The AMSDOS ROM, was quite advanced for the home computer market. Under the covers the developers enabled you to achieve a lot in terms of reading, writing and manipulating disk data. In fact, most of what I present here can be achieved with the correct manipulation of the eXtended Disk Parameter Block (XPDB), either used undocumented routines built into the ROM, or created their own. DiscSys Protection system, is a prime example of this. The Author used their indepth knowledge of the AMSDOS Rom to create a Disk that couldn’t be copied using the existing CP/M Tools of the time. It had the advantage of code re-use, reducing the footprint of the loader code required.

I wanted more control. Learning to interface directly with the controller had advantages achieving more, but also a steeper learning curve if you’re not going to use what the system developers already provided you.

First Steps

There are a number of stages to enable access to the Disk and the Disk Controller, some of which needs carefully calculated timing. In addition some logical steps need to be taken. Going forward, I’ll break some of these down. Most operations require the Disk Motor to be spun up, running at the correct speed, Some Operation/Command to execute, and Stop the Disk Motor when all operations are complete.

I’ll go through the following :-

- STOP / START the Disk Motor

- Command Phases

- Recalibrate (Move to Track 0)

- Seek

- Read a Sector

- Write a Sector

- Format a Track

- How the start of Track is known.

- Full Source Code

- Appendix of Status Registers.

MOTOR ON/MOTOR OFF

The Amstrad CPC implements access to the Disk Controller via Ports #FA7E and #FB7E.

Switching the Drive Motor ON/OFF is simply a case of using these BASIC commands :-

OUT &FA7E,1 : REM Switch the Drive Motor ON

OUT &FA7E,0 : REM Switch the Drive Motor OFF

Try it and see for yourself.

In assembler, i created the following in my DDFDC Library. It does a bit extra like preserve registers and adds a delay to wait for the drive to start spinning up to speed. You can achieve the same in much fewer bytes as you’ll see further down.

Motor On/Off Code Snippet

motoron

DI ; All Reg. Preserved

PUSH hl

PUSH bc

PUSH af

LD bc,#fa7e

LD a,1

OUT (c),a

LD hl,0

LD b,2

motoron1 ; Pause Loop To Allow Motor To Pick Up

DEC hl

LD a,h

OR l

JR nz,motoron1

DJNZ motoron1

POP af

POP bc

POP hl

RET ; Exit All Reg. Preserved

motoroff

PUSH bc

PUSH af ; All Reg. Preserved

LD bc,#fa7e

XOR a

OUT (c),a

POP af

POP bc

RET ; Quit All Reg. Intact

A few more commands than BASIC, you can shorten it to :-

motoron

LD A,1

motorctl

LD BC,#FA7E

OUT (C),A

RET

motoroff

XOR A

JR motorctl

The first motor on routine sets a delay loop to give the drive to spin up to speed. Amstrad CPC Drives are expected to spin at approximately 300 rpm, though the controller IC allows some variable tolerance of around +/- 10%.

That’s the easy bit!

Drive Command Phases

The µPD765A Controller typically uses three phases of command to complete command execution. There are some commands that don’t have a results phase, or an execution phase. These are shown in the Specification, but I’ll cover the common scenario’s here.

- Command Phase

- Execution Phase

- Read Data

- Write Data

- Results Phase

These phases are documented in the µPD765A Controller specification, though they’re not the most user friendly explanations… looking back I now realise how technical these documents are… As a teenager they seemed straight forward, nearly 40 years later I’m having to re-read/re-learn all over again.

Before going into each of the commands, I’ll describe the code I write in the 80’s to implement the interface to the controller.

Command Phase

Each of the phases of the controller are time critical, requiring 13µs pause between each command and parameter issued. You can jump to the code below which shows how I approached the problem.

Port #FB7E is used to Read the Main Register of the Disk Controller. #FB7F is used to READ/WRITE data to the Controller. To make it easier, The LD DE,command_table is a simple pointer to a table of commands and parameters.

The first byte in that table will be the number of commands needed to send. The flowchart below shows what’s going on in the code. For example, the Recalibrate command requires two parameters to be passed to the controller, #07, #00, where #07 is the command and #00 is the drive number and head we want to recalibrate. The table contains a length byte (#02) at the start, it’s used to tell our code we’re passing two bytes of data.

;

; **** COMMAND DATA FOR RECALIBRATE ****

;

RECALCOM DEFB 2 ; 2 Parameters

DEFB 7 ; Command Code For RECALIBRATE

DEFB 0 ; Which Drive

It’s probably easier to show the flow of the Command Phase to help understand the code.

We need to ensure the controller is ready to receive our commands. To achieve this, we read the Main Status Register using A = INP(#FB7E), using the IN A,(C) assembler command.

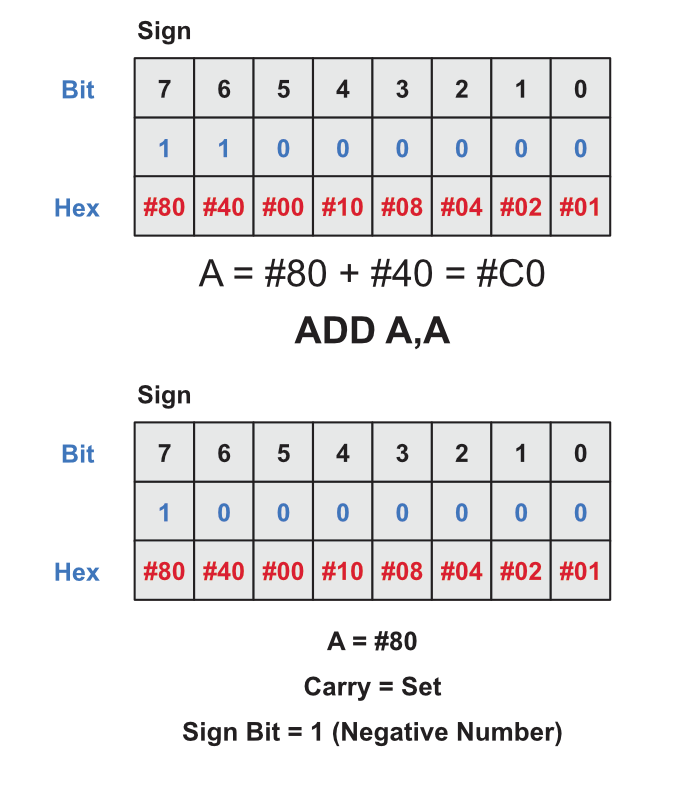

We test the value of Bit 7 and Bit 6 using a simple ADD A,A command.

ddfdc1 ; Is Drive Ready To Accept Command ?

IN a,(c)

ADD a,a

JR nc,ddfdc1

JP m,ddfdc1 ; If Not Then Wait

Why? We need to look at the Main Status Register from the controller.

- Bit 7 (RQM – Request for Master) is set to 1 when ready to receive data.

- Bit 6 (DIO – Data Input/Output) is set to 0 when in READ mode, 1 if Write mode.

We could just test bit 7 and bit 6 individually, or compare to a value #80… but remember we’re in tight time critical code, and this is a more elegant solution.

ADD A,A is the same as A = A * 2, the Carry Flag will be Set if an overflow condition occurs. For example #80 or 128 results in the answer 256. The accumulator will become #00 and the Carry Flag will be Set to indicate there’s more to the answer. In addition, Bit 7 is also used to indicate a negative number.

If the data read from the Main Status Register has Bit 7 = 0, then Carry will not be set regardless of the other bits, so we continue reading until Bit 7 is set. I.e. any original value less than 128 of #80 when doubled can not be greater than 254.

#80 * 2 = #100, A = #00 and Carry is Set.

We need the Controller to be in Ready for READ Mode, (Ready to READ OUR COMMANDS – Transfer from Processor to Data Register) hence Bit 6 must be 0 or reset. The ADD A,A also checks this for us? How?

The JP M,ddfdc1 command. This means the S – Sign Register is set, meaning Bit 7 is now set. Bit 6 = #40, #40 * 2 = #80.

Check this for your self… By experimenting with the code below in your assembler and monitor program.

ORG #A000

start

ENT $

LD A,#80

ADD A,A

RET NC ; Carry Always Set

LD A,#40

ADD A,A

RET M ; Always return as A=#80 Sign is Set

LD A,#C0

ADD A,A

JP M,start ; Won't be reached without changing A above

If the main status register = #Cx (RQM and DIO) set, then both Carry and Minus will be set, we continue to loop until the Controller is ready to Receive our Commands. Clever eh? and all in six bytes.

Code Fragment for the FDC Command Phase

;

; **** DDFDC COMMAND PHASE ****

; DE = Command Table Data

;

ddfdccom ; DDFDC Command Phase

LD bc,#fb7e

PUSH bc

LD a,(de) ; Get Number Of Parameters

ddfdc

PUSH af ; Preserve Counter

INC de

ddfdc1 ; Is Drive Ready To Accept Command ?

IN a,(c)

ADD a,a

JR nc,ddfdc1

JP m,ddfdc1 ; If Not Then Wait

LD a,(de)

INC c

OUT (c),a ; Give DDFDC Command @ Port #FB7F

DEC c

LD a,5

ddfdcp ; Wait 13 uS

DEC a

JR nz,ddfdcp

POP af

DEC a

JR nz,ddfdc

POP bc ; On Return BC=#FB7E

RET ; Quit

Execution Phase (Read/Write)

The command phase was fairly straight forward, the code simply waits for the state of the controller to be ready to receive our commands, then we send the command and the command parameters in sequence 13µs apart.

Depending on the FDC Command we’re invoking, the execution phase is either :-

- READ Data From the Controller. CALL ddfdcexc

- WRITE Data to the Controller. CALL ddfdcwri

We READ Data if we’re scanning Sector IDs, Sector/Track Data, Validating Data etc.

WRITE Mode would be for Formatting Tracks, Writing Sector information and so forth.

The code for the execution phase is fairly straight forward, we pass the Drive we want to access in the Accumulator (0 = Drive A, 1 = Drive B), we then OR this with #20 (The RQM Execution Mode Bit). And use Self-Modifying code to check that the Drive is still in execution phase for that drive later in the loop. HL is set to point to a location in memory where the data will be stored.

The loop simply checks the Drive status, and reads data from the PORT until the Controller signals there’s no more data to be read.

Equally when WRITING Data to the Controller, the logic is similar except we send data pointed to in HL until the controller signals to stop. It’s the easier phase.

Code Fragment for the FDC Execution Phase

;

ddfdcexc ; DDFDC Execution Phase - DATA IN

LD a,(drive)

OR #20

LD (ddfdexc2-1),a

ddfdcexd

LD bc,#fb7e

IN a,(c)

CP #c0

JR c,ddfdexc1

ddfdexc0

INC c ; Point To #FB7F - DATA REGISTER

IN a,(c) ; Get byte from port

LD (hl),a ; Store it

DEC c ; Restore Port To Main Status Reg.

INC hl ; HL+1

ddfdexc1

IN a,(c)

JP p,ddfdexc1 ; Drive Not Finished Output So Wait

AND #20 ; Main Status Reg=Execution Phase Start

ddfdexc2

JR nz,ddfdexc0 ; If Not Finished Loop ddfdexc

RET ; Else Quit

;

; **** DDFDC EXECUTION PHASE DATA TO SYSTEM ****

;

ddfdcwri ; DDFDC Write Into Data Register

LD bc,#fb7e ; Point To MAIN STATUS REG

LD a,(drive)

OR #20

LD (ddfdcw3-1),a

JR ddfdcw2 ; Wait Till DDFDC Ready.

ddfdcw1

INC c ; Point To Data Port

LD a,(hl) ; Get Byte To Place

INC hl ; HL+1

OUT (c),a ; Output To Port #FB7F

DEC c ; Restore Port

ddfdcw2

IN a,(c)

JP p,ddfdcw2 ; If Drive Not Ready Loop ddfdcw2

AND #20

ddfdcw3

JR nz,ddfdcw1 ; Is All Output Finished ?

RET ; Quit

;

The Results Phase

Finally we enter the results phase. The controller will send data informing us of the success or otherwise of the command we attempted to execute.

The code should start looking familiar now, as we add Bit 5 to the Drive number to check for readiness of the controller.

We also check the controller is both ready and the the DIO bit is set, a simple compare is all that’s needed here.

The results are written to a buffer pointed to in HL.

LD A,Drive

LD HL, Results_Buffer

CALL ddfdcres

The results buffer will contain information on the Drive Registers ST0, ST1, ST2, Track Number, Drive, Sector Number and Sector Size though these bytes are defined in the Specification.

Code Fragment for the FDC Results Phase

;

; **** DDFDC RESULTS PHASE ****

;

ddfdcres ; DDFDC Result Phase

LD a,(drive)

OR #10

LD (ddfdresq-1),a

ddfdcret

IN a,(c)

CP #c0 ; Is DDFDC Ready ?

JR c,ddfdcret ; If Not Wait

INC c

IN a,(c) ; Get Byte From DATA REG

LD (hl),a ; Store it

DEC c ; Restore Data Reg.

INC hl ; HL+1

LD a,5

ddfdresp ; Wait 13 uS

DEC a

JR nz,ddfdresp

IN a,(c)

AND #10 ; Has Results Finished ?

ddfdresq

JR nz,ddfdcret ; If Not Loop ddfdcres

RET ; Quit

Putting it all together.

Now you have the assembly code basics for accessing the controller, it’s time to pull it all together and do something useful…

We need to implement some of the FDC Commands. Whilst many emulators do an awesome job of implementing Support, if you can try this on real hardware you will see some subtle differences. Mainly in the way the DSK File format masks some of the intricacies of Disk Formats and Status Codes, they will be predictable, physical and ageing disks won’t…

Recalibrate the Drive

Not quite what you may think here, this command doesn’t test speed or calibration of the stepper motors etc, it’s basically a way for the controller to know it’s start position after powering on your machine. Where is the drive head located now? Since the controller has no memory, it has no way of knowing which track it’s currently aligned to or if it moved after power off.

The recalibrate commands seeks to move the Drive Head to Track 0. A micro switch signals the controller the head is in the home position. From here on in, the drive will operate without the need to execute this command.

When Recalibrating the Drive Head, this is associated with the Sense Drive Status Command to ensure the operation is complete.

In likelihood, AMSDOS will have completed this task the moment you accessed a Disk in your Amstrad.

In all your disk operations you need to move the drive head up and down the disk to point to the correct track. There are a few steps you need to complete this.

- Set the Drive ID (0 – Drive A, 1 – Drive B)

- Set the Track you want to move to.

I’ve coded my library as follows.

- Is requested Track same as Current Track?

- If Yes, Quit no work to do.

- If Requested Track = 0?

- If Yes, issue the Recalibrate Command.

- Else Send SEEK Command

- Wait until the Sense Interrupt shows the operation is complete.

Below are the commands in easier to read format, compared to the PDF that’s available.

RECALIBRATE Command

The Recalibration command doesn’t have an execution or status command phase.

| Offset | Command | Definition |

|---|---|---|

| 0 | #07 | Recalibrate Command |

| 1 | #00 | The Drive number to Recalibrate |

SEEK Track Command

Whenever moving the Drive head to a different Track, you must always execute the SEEK command.

| Offset | Command | Definition |

|---|---|---|

| 0 | #0F | Seek Command |

| 1 | #00 | Drive Number, 0 = A, 1 = B, Bit 2 can be set if you have dual heads. |

| 2 | #00 | Destination Track, Usually 0 – 41, anything higher than this will likely damage the 3″ Disk Drive. If you have a 3.5″ Disk Connected, you can access higher tracks. |

SENSE INTERRUPT STATUS COMMAND

| Offset | Command | Definition |

|---|---|---|

| 0 | #08 | Sense Interrupt Status Command |

| Offset | Response | Definition |

|---|---|---|

| 0 | ST 0 | Status Register 0 Data – See Appendix |

| 1 | PCN – Present Cylinder Number | What is the current Track we’re on? |

SENSE DRIVE STATUS COMMAND

| Offset | Command | Definition |

|---|---|---|

| 0 | #04 | Sense Drive Status Command |

| 1 | #00 | Drive Number, 0 = A, 1 = B, Bit 2 can be set if you have dual heads. |

| Offset | Response | Definition |

|---|---|---|

| 0 | xx | Status Register 3 Data – See Appendix |

SEEK Track Code Usage

The snippet below shows how to invoke the movtrak command.

D = Track Number (0-41)

E = Drive Number (0 = A, 1 = B)

If Track 0 is requested the code will automatically perform a recalibration.

LD D,trackNumber

LD E,Drive

CALL movtrak

Seek, Recalibrate and Sense Drive Commands Code Snippet

;

; **** Move Drive Head To Track T ****

;

drivicl DEFB 0

movtrak ; On Entry D = Destination Track

PUSH af

PUSH bc

PUSH de

PUSH hl ; Preserve Registers

LD a,e

OR #20

LD (drivicl),a

CALL senseint ; Get Current Track Position

LD a,(sense+1)

SUB d ; Is Destination Track Current Track ?

JR z,movtrake ; If So Quit

LD a,d ; A = Track

OR a ; Is Destination Track 0

JR z,trak0 ; If So Then Trak0

CALL seek ; Give DDFDC SEEK Command

movtrak1 ; Use This Since No DMA

CALL senseint ; Has Drive Reached Destination ?

LD hl,drivicl

LD a,(sense)

CP (hl)

JR nz,movtrak1 ; If Not Loop movtrak1

movtrake ; Quit Routine

POP hl

POP de

POP bc

POP af

RET ; Preserved Registers

trak0

CALL recalib ; Recalibrate (Move To Track 0)

trak01

CALL senseds ; Call SENSE DRIVE STATUS

LD a,(hl)

AND %10000 ; Has Drive Head Reached TRK 0

JR z,trak01 ; If Not Loop

JR movtrake ; Restore Regs & Quit

;

; **** SENSE DRIVE STATUS ****

;

senseds

LD a,(drive)

LD (SenseCde+2),a

LD de,SenseCde

CALL ddfdccom

LD hl,sendst ; Pointer To Put Resultant Data

CALL ddfdcres

DEC hl ; On Exit HL=Address Of Status Reg. 3

RET ; Quit

;

; **** RECALIBRATE DRIVE HEAD (TRACK 0) ****

;

recalib ; Recalibrate

LD de,RECALCOM

LD a,(drive)

LD (RECALCOM+2),a

JP ddfdccom

;

; **** SENSE INTERUPT STATUS ****

;

senseint ; Sense Interupt Status

PUSH de ; Preserve DE

LD de,SENSE_INT

CALL ddfdccom

LD hl,sense

CALL ddfdcres ; Call & Quit

POP de

RET

;

; **** SEEK COMMAND MOVE TRACK HEAD ****

;

seek ; SEEK Entry D=Track

PUSH de

LD (Seek_DT+3),a

LD a,(drive)

LD (Seek_DT+2),a

LD de,Seek_DT

CALL ddfdccom

POP de

RET

;

; **** COMMAND DATA FOR SENSE DRIVE STATUS ****

;

SenseCde

DEFB 2 ; 2 Parameters

DEFB 4 ; Code For SENSE DRIVE STATUS

DEFB 0 ; Drive

;

; **** COMMAND DATA FOR SEEK ****

;

Seek_DT ; Seek Codes For Command

DEFB 3 ; 3 Parameters

DEFB 15 ; Command For Seek

DEFB 0 ; Drive

DEFB 0 ; Destination Track

;

; **** COMMAND DATA FOR SENSE INTERUPT STATUS ****

;

SENSE_INT DEFB 1 ; One Parameter

DEFB 8 ; Command Code For SENSE INTERRUPT STATE

Reading Sectors

Now we have the “Basics” out of the way, you’ll be wanting to do something useful like Reading Data …

Thankfully this and other commands are straight forward.

The table located at readcomd contains all the information needed to read a sector, you need to set these parameters accordingly, helper function patchrwd attempts to do this for you.

READ Command

| Offset | Command | Definition |

|---|---|---|

| 0 | #46 | Read Sector Command from MFM Disk |

| 1 | #00 | Drive Number, 0 = A, 1 = B, Bit 2 can be set if you have dual heads. |

| 2 | #00 – #29 | Cylinder – Track Number to Read |

| 3 | #00 – #01 | Head Number, 0 = Drive A, 1 = Drive B |

| 4 | #xx | Sector ID to Read, i.e. #C1 for First Sector of DATA Format |

| 5 | #00-#05 | N – Sector Size 2^(7+n) |

| 6 | #xx | Last Sector ID to Read Sequentially. For example you could set it up to Read all sectors from #C4 to #C7 |

| 7 | #xx | GAP#3 Length |

| 8 | #FF | Data Length, if less than 255 bytes, change this to the amount you want to Read. |

| Offset | Response | Definition |

|---|---|---|

| 0 | ST 0 | Status Register 0 |

| 1 | ST 1 | Status Register 1 |

| 2 | ST 2 | Status Register 2 |

| 3 | C | Cylinder/Track Number |

| 4 | H | Head Number |

| 5 | R | Sector Number Read |

| 6 | N | Size of Sector Read 2^(7+N) |

It’s important to check the status of the registers after a read operation to check if completed successfully.

The command response is stored in readcomr, check the status to ensure all has gone as expected.

- Set HL to point to a memory location to load the sector.

- E = Drive Number

- D = Track Number

- C = Sector ID to Read

- CALL readsect

Read Sector Code Fragment

readsect ; ENTRY HL=BUFFER E=DRIVE D=TRK C=SECTR

PUSH af

PUSH bc

PUSH de

PUSH hl ; Preserve Registers

CALL movtrak ; Move To Appropriate Track

PUSH hl

LD hl,readcomd+2

CALL patchrwd ; Patch Read Data

LD de,readcomd

CALL ddfdccom ; Set Up Command

POP hl

CALL ddfdcexc ; Get Bytes From EXECUTION PHASE

LD hl,readcomr

CALL ddfdcres ; Get Result From Read Command

POP hl

POP de

POP bc

POP af

RET

;

; **** PATCH READ WRITE DATA FOR READ/WRITE COMMAND ****

;

patchrwd ; Patch Read Write Data

PUSH hl

PUSH af

LD a,e ; A=Drive

LD (hl),a

INC hl

INC hl ; Point HL To Head Number

LD (hl),a ; Store Head Number

DEC hl ; Point To Track Data

LD a,d ; A = Track

LD (hl),a ; Store Track Number

INC hl

INC hl ; Point To Sector

LD a,c ; A = Sector

LD (hl),a ; Store It

INC hl

INC hl ; Point To End Of Track

LD (hl),a ; Store Sector

DEC hl ; Point To Sector Size

LD a,(sectsize) ; Get Sector Size From XDPB

LD (hl),a ; Store It

INC hl

INC hl ; Point To Gap Length

LD a,(gap3rw) ; A = Gap #3 For READ/WRITE

LD (hl),a ; Store It

INC hl ; Point To Data Length

LD a,(dataleng) ; A=Sector Length

LD (hl),a ; Store It

POP af

POP hl

RET

;

; **** COMMAND DATA FOR READ SECTOR ****

;

readcomd ; Read Command Data

DEFB 9 ; 9 Parameters

DEFB #46 ; READ DATA Command Alter To #4C Del.

DEFB 0 ; Drive

DEFB 0 ; Track

DEFB 0 ; Head Number

DEFB #C1 ; Sector To Read

DEFB 2 ; Number Of Data Bytes Per Sector

DEFB #C1 ; End Of Track

DEFB 0 ; Gap #3 - Generally #2a

DEFB #FF ; Data Length - Sect Size < 256

;

; **** READ DATA RESULTANT BYTES FROM RESULT PHASE ****

;

readcomr ; Read Command Result Table

DEFB 0 ; Status Register 0

DEFB 0 ; Status Register 1

DEFB 0 ; Status Register 2

DEFB 0 ; Track Number

DEFB 0 ; Head Number

DEFB 0 ; Sector Number

DEFB 0 ; Sector Size

Writing Sectors

If you followed through the READ Sector code above you won’t be surprised how similar these routines are.

The command response is stored in writcomr, check the status to ensure all has gone as expected.

- Set HL to point to the memory location of the data to write.

- E = Drive Number

- D = Track Number

- C = Sector ID to Write

- CALL writsect

WRITE DATA COMMAND

| Offset | Command | Definition |

|---|---|---|

| 0 | #45 | Write Sector Command from MFM Disk |

| 1 | #00 | Drive Number, 0 = A, 1 = B, Bit 2 can be set if you have dual heads. |

| 2 | #00 – #29 | Cylinder – Track Number to Read |

| 3 | #00 – #01 | Head Number, 0 = Drive A, 1 = Drive B |

| 4 | #xx | Sector ID to Write, i.e. #C1 for First Sector of DATA Format |

| 5 | #00-#05 | N – Sector Size 2^(7+n) |

| 6 | #xx | Last Sector ID to Write Sequentially. For example you could set it up to Write all sectors from #C4 to #C7 |

| 7 | #xx | GAP#3 Length |

| 8 | #FF | Data Length, if less than 255 bytes, change this to the amount you want to write. |

| Offset | Response | Definition |

|---|---|---|

| 0 | ST 0 | Status Register 0 |

| 1 | ST 1 | Status Register 1 |

| 2 | ST 2 | Status Register 2 |

| 3 | C | Cylinder/Track Number |

| 4 | H | Head Number |

| 5 | R | Sector Number Written |

| 6 | N | Size of Sector Written 2^(7+N) |

Write Data to Sector Code Snippet

;

; **** WRITE DATA To TRACK & SECTOR ****

;

writsect ; Entry HL=DATA ADDR D=TRK E=DRV C=SECT

PUSH af

PUSH bc

PUSH de

PUSH hl ; Preserve Registers

CALL movtrak ; Move To Track D

PUSH hl

LD hl,writcomd+2 ; Point To Command DATA Table

CALL patchrwd ; Patch Write Data For TRACK & SECTOR

LD de,writcomd ; Point To Command Data

CALL ddfdccom ; Start COMMAND PHASE

POP hl ; Restore HL = DATA To Write

CALL ddfdcwri ; Write It To Disk

LD hl,writcomr ; HL=Write Command Return

CALL ddfdcres ; Call Up Result Phase

POP hl

POP de

POP bc

POP af ; Restore Registers

RET ; Exit Routine

;

; **** COMMAND CODE FOR DDFDC WRITE SECTOR ****

;

writcomd ; Write Command Data

DEFB 9 ; 9 Parameters

DEFB #45 ; WRITE DATA Command Alter #49 Del. Dta

DEFB 0 ; Drive

DEFB 0 ; Track

DEFB 0 ; Head Number

DEFB 0 ; Sector To Read

DEFB 0 ; Number Of Data Bytes Per Sector

DEFB 0 ; End Of Track

DEFB 0 ; Gap #3 - Generally #2a

DEFB #ff ; Data Length - Sect Size < 256

;

; **** WRITE DATA RESULTANT BYTES FROM RESULT PHASE ****

;

writcomr ; Write Command Result Table

DEFB 0 ; Status Register 0

DEFB 0 ; Status Register 1

DEFB 0 ; Status Register 2

DEFB 0 ; Track Number

DEFB 0 ; Head Number

DEFB 0 ; Sector Number

DEFB 0 ; Sector Size

Formatting A Track

You’ve learned the basics of reading and writing sectors to disk, how about Formatting a Track? Again this is really easy, and where you can get creative too! Many a protection system designer started off messing around with the various parameters required to make disks that could be read by a bespoke program but copying them using CP/M tools was not possible. This helped boost a cottage industry of specialist copiers, and tools like Discology and Nirvana came into play. They were very good at analysing disks and creating a faithful copy for many of the nuanced protection systems designed out there.

- LD HL,Format_Table

- LD D,Track

- CALL format

The Format_Table of code contains a data block consisting of Track, Head, Sector ID, Sector Size and would look like the snippet below for a DATA Format disk of 9 Sectors. Remember with physical hardware it was necessary to interlace the sectors for optimal performance through AMSDOS. However if you’re creating your own protection system, you can double the speed/performance of your program by sequentially numbering the sector IDs since you’re more likely to be reading data from disk in a tight loop.

;

; **** Header Buffer For Formatting A Disk ****

;

fo ; Format Disk

DEFB 0,0,#c1,2 ; Data For Sector Numbers To Format

DEFB 0,0,#c6,2 ; In This Case DATA Format

DEFB 0,0,#c2,2

DEFB 0,0,#c7,2

DEFB 0,0,#c3,2

DEFB 0,0,#c8,2

DEFB 0,0,#c4,2

DEFB 0,0,#c9,2

DEFB 0,0,#c5,2

FORMAT TRACK COMMAND

| Offset | Command | Definition |

|---|---|---|

| 0 | #4D | Format Track Command for MFM DIsk |

| 1 | #00 | Drive Number, 0 = A, 1 = B, Bit 2 can be set if you have dual heads. |

| 2 | #00-#05 | N – Sector Size 2^(7+n) |

| 3 | #xx | Number of Sectors per Track |

| 4 | #xx | GAP#3 Length |

| 5 | #xx | Filler Byte (Usually #E5) |

| Offset | Response | Definition |

|---|---|---|

| 0 | ST 0 | Status Register 0 |

| 1 | ST 1 | Status Register 1 |

| 2 | ST 2 | Status Register 2 |

| 3 | C | Cylinder/Track Number |

| 4 | H | Head Number |

| 5 | R | Sector Number |

| 6 | N | Size of Sector 2^(7+N) |

FORMAT Track Code Snippet

;

; **** Format A Track Of Data ****

;

format ; Entry:- HL=Header Info.Buff. D=Track

PUSH af

PUSH bc

PUSH de

PUSH hl ; Preserve Registers

LD a,e

LD (drive),a ; Which Drive

CALL movtrak ; E=Drive

PUSH hl ; Locate Drive Head To Correct Track

;

LD a,(sectsize)

LD (formcode+3),a ; Store For Command Phase

LD a,(sect_trk)

LD (formcode+4),a ; Store Sectors Per Track

LD a,(gap3f)

LD (formcode+5),a ; Store GAP#3 For Formatting

LD a,(filler)

LD (formcode+6),a ; Store Filler Byte

LD de,formcode ; Codes For Command Phase

format1

CALL ddfdccom ; Get Bytes And Act On 'em

POP hl ; Restore Registers

CALL ddfdcwri ; Write Bytes To Disk

LD hl,formret ; Return Status

CALL ddfdcres ; Get status

POP hl

POP de

POP bc

POP af

RET ; Quit with all registers intact

;

; **** Header Buffer For Formatting A Disk ****

;

fo ; Format Disk

DEFB 0,0,#c1,2 ; Data For Sector Numbers To Format

DEFB 0,0,#c6,2 ; In This Case DATA Format

DEFB 0,0,#c2,2

DEFB 0,0,#c7,2

DEFB 0,0,#c3,2

DEFB 0,0,#c8,2

DEFB 0,0,#c4,2

DEFB 0,0,#c9,2

DEFB 0,0,#c5,2

formcode ; Format Track Data

DEFB 6 ; 6 Paramters

DEFB #4d ; Code For Formatting

drive DEFB 0 ; Drive

DEFB 2 ; Size of Sectors 2 ^ (N+7)

DEFB 9 ; No. of Sector Per Track

DEFB #2a ; Gap Length

DEFB #e5 ; Data Pattern = Filler Byte

;

; **** FORMAT RESULTS PHASE TABLE ****

;

formret ; Resultant Data From FORMAT TRACK

DEFB 0 ; ST0

DEFB 0 ; ST1

DEFB 0 ; ST2

DEFB 0 ; Track

DEFB 0 ; Head

DEFB 0 ; Sector

DEFB 0 ; Size Of Sector

;

;Default Numbers For 9 Sectors Per Track 512 Bytes Per Sector GAP #3=#2a

;

XDPB ; For My Own Use (Alternative XPB)

;

filler DEFB #e5 ; Filler Byte When Formatting

sect_trk DEFB 9 ; Number Of Sectors Per Track

sectsize DEFB 2 ; Size Of Sectors

gap3rw DEFB #2a ; GAP #3 For Read/Write

gap3f DEFB #52 ; GAP #3 For Formatting

Index Marker

How does the drive know where the start of track is?

If you pull back the protective cover of the disk you’ll spot close to the centre of the disk, a smaller hole, you may need to spin the disk around to line it up, like I have below. This method isn’t limited to the Three inch disks, many floppy’s, from the eight inch, five and quarter, three and half etc use this method. There are some disks that don’t have this indicator, those are out of scope from this primer.

As the disk spins, that little hole will appear very briefly (Around 300 times a minute), where an optical signal is sent to the controller to show the start of each disk revolution. When this light is detected (With the image below a slowed down animation, shows a green light), a signal is sent to the controller. This method ensures some reliability in reading the data from the start of each track.

Full Source Code for Direct Access to the Disk Controller

Below is the complete source code from my assembler routines to access the Amstrad CPC Disk Controller directly. Firmware not required, which enabled me to easily manipulate disk data directly.

;

ORG #9d00 ; Alternative DDFDC Commands

ENT $ ; Version 9.89 - Jason Brooks

DI

CALL motoron

LD hl,#100

LD d,0

LD e,1

CALL readtrak

CALL motoroff

RET

init

PUSH bc

LD hl,fo

LD b,9

init1

LD (hl),d

INC hl

INC hl

INC hl

INC hl

DJNZ init1

POP bc

RET

motoron

DI ; All Reg. Preserved

PUSH hl

PUSH bc

PUSH af

LD bc,#fa7e

LD a,1

OUT (c),a

LD hl,0

LD b,2

motoron1 ; Pause Loop To Allow Motor To Pick Up

DEC hl

LD a,h

OR l

JR nz,motoron1

DJNZ motoron1

POP af

POP bc

POP hl

RET ; Exit All Reg. Preserved

motoroff

PUSH bc

PUSH af ; All Reg. Preserved

LD bc,#fa7e

XOR a

OUT (c),a

POP af

POP bc

RET ; Quit All Reg. Intact

readtrak

DI

PUSH af

PUSH bc

PUSH de

PUSH hl

LD a,e

LD (drive),a

CALL movtrak

LD a,e

LD (READTRAK+2),a

LD a,d

LD (READTRAK+3),a

LD de,readcomd

CALL ddfdccom

CALL ddfdcexc

CALL ddfdcres

POP hl

POP de

POP bc

POP af

RET

;

rdelsect ; Read Deleted Sector

LD a,#4c ; Command Code For READ DELETED DATA

LD (readcomd+1),a ; Store It

CALL readsect ; Read In Sector

LD a,#46 ; Command Code For READ DATA

LD (readcomd+1),a ; Restore Command Code

RET ; Exit

readsect ; ENTRY HL=BUFFER E=DRIVE D=TRK C=SECTR

PUSH af

PUSH bc

PUSH de

PUSH hl ; Preserve Registers

CALL movtrak ; Move To Approprite Track

PUSH hl

LD hl,readcomd+2

CALL patchrwd ; Patch Read Data

LD de,readcomd

CALL ddfdccom ; Set Up Command

POP hl

CALL ddfdcexc ; Get Bytes From EXECUTION PHASE

LD hl,readcomr

CALL ddfdcres ; Get Result From Read Command

POP hl

POP de

POP bc

POP af

RET

wdeldata ; Write Deleted Data

PUSH af ; Preserve AF

LD a,%1001001 ; Comand For WRITE DELETED DATA

LD (writcomd+1),a ; Store Command In Data String

CALL writsect ; Call Up Normal WRITE SECTOR

LD a,%1000101 ; Command For WRITE DATA

LD (writcomd+1),a ; Restore Command In Data String

POP AF ; Restore AF

RET ; Quit

;

; **** WRITE DATA To TRACK & SECTOR ****

;

writsect ; Entry HL=DATA ADDR D=TRK E=DRV C=SECT

PUSH af

PUSH bc

PUSH de

PUSH hl ; Preserve Registers

CALL movtrak ; Move To Track D

PUSH hl

LD hl,writcomd+2 ; Point To Command DATA Table

CALL patchrwd ; Patch Write Data For TRACK & SECTOR

LD de,writcomd ; Point To Command Data

CALL ddfdccom ; Start COMMAND PHASE

POP hl ; Restore HL = DATA To Write

CALL ddfdcwri ; Write It To Disk

LD hl,writcomr ; HL=Write Command Return

CALL ddfdcres ; Call Up Result Phase

POP hl

POP de

POP bc

POP af ; Restore Registers

RET ; Exit Routine

;

; **** PATCH READ WRITE DATA FOR READ/WRITE COMMAND ****

;

patchrwd ; Patch Read Write Data

PUSH hl

PUSH af

LD a,e ; A=Drive

LD (hl),a

INC hl

INC hl ; Point HL To Head Number

LD (hl),a ; Store Head Number

DEC hl ; Point To Track Data

LD a,d ; A = Track

LD (hl),a ; Store Track Number

INC hl

INC hl ; Point To Sector

LD a,c ; A = Sector

LD (hl),a ; Store It

INC hl

INC hl ; Point To End Of Track

LD (hl),a ; Store Sector

DEC hl ; Point To Sector Size

LD a,(sectsize) ; Get Sector Size From XDPB

LD (hl),a ; Store It

INC hl

INC hl ; Point To Gap Length

LD a,(gap3rw) ; A = Gap #3 For READ/WRITE

LD (hl),a ; Store It

INC hl ; Point To Data Length

LD a,(dataleng) ; A=Sector Length

LD (hl),a ; Store It

POP af

POP hl

RET

;

; **** Format A Track Of Data ****

;

format ; Entry:- HL=Header Info.Buff. D=Track

PUSH af

PUSH bc

PUSH de

PUSH hl ; Preserve Registers

LD a,e

LD (drive),a ; Which Drive

CALL movtrak ; E=Drive

PUSH hl ; Locate Drive Head To Correct Track

;

LD a,(sectsize)

LD (formcode+3),a ; Store For Command Phase

LD a,(sect_trk)

LD (formcode+4),a ; Store Sectors Per Track

LD a,(gap3f)

LD (formcode+5),a ; Store GAP#3 For Formatting

LD a,(filler)

LD (formcode+6),a ; Store Filler Byte

LD de,formcode ; Codes For Command Phase

format1

CALL ddfdccom ; Get Bytes And Act On 'em

POP hl ; Restore Registers

CALL ddfdcwri ; Write Bytes To Disk

LD hl,formret ; Return Status

CALL ddfdcres ; Get status

POP hl

POP de

POP bc

POP af

RET ; Quit with all registers intact

;

; **** Read Sector ID ****

;

readid

PUSH af ; Entry E=drive 0=A 1=B

PUSH bc

PUSH de

LD a,e

LD (Read_ID+2),a ; Store Drive

LD hl,diskid

PUSH hl

LD de,Read_ID

CALL ddfdccom

CALL ddfdcres

POP hl ; Exit Cond. HL=Disk Id, All Reg. Pres.

POP de

POP bc

POP af

RET

;

; **** Move Drive Head To Track T ****

;

drivicl DEFB 0

movtrak ; On Entry D = Destination Track

PUSH af

PUSH bc

PUSH de

PUSH hl ; Preserve Registers

LD a,e

OR #20

LD (drivicl),a

CALL senseint ; Get Current Track Position

LD a,(sense+1)

SUB d ; Is Destination Track Current Track ?

JR z,movtrake ; If So Quit

LD a,d ; A = Track

OR a ; Is Destination Track 0

JR z,trak0 ; If So Then Trak0

CALL seek ; Give DDFDC SEEK Command

movtrak1 ; Use This Since No DMA

CALL senseint ; Has Drive Reached Destination ?

LD hl,drivicl

LD a,(sense)

CP (hl)

JR nz,movtrak1 ; If Not Loop movtrak1

movtrake ; Quit Routine

POP hl

POP de

POP bc

POP af

RET ; Preserved Registers

trak0

CALL recalib ; Recalibrate (Move To Track 0)

trak01

CALL senseds ; Call SENSE DRIVE STATUS

LD a,(hl)

AND %10000 ; Has Drive Head Reached TRK 0

JR z,trak01 ; If Not Loop

JR movtrake ; Restore Regs & Quit

;

; **** SENSE DRIVE STATUS ****

;

senseds

LD a,(drive)

LD (SenseCde+2),a

LD de,SenseCde

CALL ddfdccom

LD hl,sendst ; Pointer To Put Resultant Data

CALL ddfdcres

DEC hl ; On Exit HL=Address Of Status Reg. 3

RET ; Quit

;

; **** RECALIBRATE DRIVE HEAD (TRACK 0) ****

;

recalib ; Recalibrate

LD de,RECALCOM

LD a,(drive)

LD (RECALCOM+2),a

JP ddfdccom

;

; **** SENSE INTERUPT STATUS ****

;

senseint ; Sense Interupt Status

PUSH de ; Preserve DE

LD de,SENSEINT

CALL ddfdccom

LD hl,sense

CALL ddfdcres ; Call & Quit

POP de

RET

;

; **** SEEK COMMAND MOVE TRACK HEAD ****

;

seek ; SEEK Entry D=Track

PUSH de

LD (Seek_DT+3),a

LD a,(drive)

LD (Seek_DT+2),a

LD de,Seek_DT

CALL ddfdccom

POP de

RET

;

; **** DDFDC COMMAND PHASE ****

;

ddfdccom ; DDFDC Command Phase

LD bc,#fb7e

PUSH bc

LD a,(de) ; Get Number Of Parameters

ddfdc

PUSH af ; Preserve Counter

INC de

ddfdc1 ; Is Drive Ready To Accept Command ?

IN a,(c)

ADD a,a

JR nc,ddfdc1

JP m,ddfdc1 ; If Not Then Wait

LD a,(de)

INC c

OUT (c),a ; Give DDFDC Command @ Port #FB7F

DEC c

LD a,5

ddfdcp ; Wait 13 uS

DEC a

JR nz,ddfdcp

POP af

DEC a

JR nz,ddfdc

POP bc ; On Return BC=#FB7E

RET ; Quit

;

ddfdcexc ; DDFDC Execution Phase - DATA IN

LD a,(drive)

OR #20

LD (ddfdexc2-1),a

ddfdcexd

LD bc,#fb7e

IN a,(c)

CP #c0

JR c,ddfdexc1

ddfdexc0

INC c ; Point To #FB7F - DATA REGISTER

IN a,(c) ; Get byte from port

LD (hl),a ; Store it

DEC c ; Restore Port To Main Status Reg.

INC hl ; HL+1

ddfdexc1

IN a,(c)

JP p,ddfdexc1 ; Drive Not Finished Output So Wait

AND #20 ; Main Status Reg=Execution Phase Start

ddfdexc2

JR nz,ddfdexc0 ; If Not Finished Loop ddfdexc

RET ; Else Quit

;

; **** DDFDC EXECUTION PHASE DATA TO SYSTEM ****

;

ddfdcwri ; DDFDC Write Into Data Register

LD bc,#fb7e ; Point To MAIN STATUS REG

LD a,(drive)

OR #20

LD (ddfdcw3-1),a

JR ddfdcw2 ; Wait Till DDFDC Ready.

ddfdcw1

INC c ; Point To Data Port

LD a,(hl) ; Get Byte To Place

INC hl ; HL+1

OUT (c),a ; Output To Port #FB7F

DEC c ; Restore Port

ddfdcw2

IN a,(c)

JP p,ddfdcw2 ; If Drive Not Ready Loop ddfdcw2

AND #20

ddfdcw3

JR nz,ddfdcw1 ; Is All Output Finished ?

RET ; Quit

;

; **** DDFDC RESULTS PHASE ****

;

ddfdcres ; DDFDC Result Phase

LD a,(drive)

OR #10

LD (ddfdresq-1),a

ddfdcret

IN a,(c)

CP #c0 ; Is DDFDC Ready ?

JR c,ddfdcret ; If Not Wait

INC c

IN a,(c) ; Get Byte From DATA REG

LD (hl),a ; Store it

DEC c ; Restore Data Reg.

INC hl ; HL+1

LD a,5

ddfdresp ; Wait 13 uS

DEC a

JR nz,ddfdresp

IN a,(c)

AND #10 ; Has Results Finished ?

ddfdresq

JR nz,ddfdcret ; If Not Loop ddfdcres

RET ; Quit

;

; **** DATA AREA BUFFERS, POINTERS Etc. ****

;

sense ; Data from RESULT PHASE OF SNSE INT ST

DEFB 0 ; ST0

DEFB 0 ; Present Track Number

;

; **** BYTE FOR SENSE DRIVE STATUS RESULT PHASE ****

;

sendst DEFB 0 ; Status Register 3

;

; **** DATA FOR COMMAND PHASE OF FORMAT A TRACK ****

;

READTRAK

DEFB 9

DEFB %1100010

DEFB 0

DEFB 0

DEFB 0

DEFB 1

DEFB 6

DEFB 1

DEFB #52

DEFB #ff

formcode ; Format Track Data

DEFB 6 ; 6 Paramters

DEFB #4d ; Code For Formatting

drive DEFB 0 ; Drive

DEFB 2 ; Size of Sectors 2 ^ (N+7)

DEFB 9 ; No. of Sector Per Track

DEFB #2a ; Gap Length

DEFB #e5 ; Data Pattern = Filler Byte

;

; **** FORMAT RESULTS PHASE TABLE ****

;

formret ; Resultant Data From FORMAT TRACK

DEFB 0 ; ST0

DEFB 0 ; ST1

DEFB 0 ; ST2

DEFB 0 ; Track

DEFB 0 ; Head

DEFB 0 ; Sector

DEFB 0 ; Size Of Sector

;

;Default Numbers For 9 Sectors Per Track 512 Bytes Per Sector GAP #3=#2a

;

XDPB ; For My Own Use (Alternative XPB)

;

filler DEFB #e5 ; Filler Byte When Formatting

sect_trk DEFB 9 ; Number Of Sectors Per Track

sectsize DEFB 2 ; Size Of Sectors

gap3rw DEFB #2a ; GAP #3 For Read/Write

gap3f DEFB #52 ; GAP #3 For Formatting

dataleng DEFB #ff

;

; **** COMMAND DATA FOR SENSE DRIVE STATUS ****

;

SenseCde

DEFB 2 ; 2 Parameters

DEFB 4 ; Code For SENSE DRIVE STATUS

DEFB 0 ; Drive

;

; **** COMMAND DATA FOR SEEK ****

;

Seek_DT ; Seek Codes For Command

DEFB 3 ; 3 Parameters

DEFB 15 ; Command For Seek

DEFB 0 ; Drive

DEFB 0 ; Destination Track

;

; **** COMMAND DATA FOR SENSE INTERUPT STATUS ****

;

SENSEINT DEFB 1 ; One Parameter

DEFB 8 ; Command Code For SENSE INTERUPT STATE

;

; **** COMMAND DATA FOR READ ID ****

;

Read_ID

DEFB 2 ; 2 Parameters

DEFB #4a ; Command Number

DEFB 0 ; Drive

;

; **** RESULTANT DATA FROM READ ID ****

;

diskid ; DISK ID Resultant Data

DEFB 0 ; ST0

DEFB 0 ; ST1

DEFB 0 ; ST2

DEFB 0 ; Track

DEFB 0 ; Head

DEFB 0 ; Sector

DEFB 0 ; Sector Size = 2 ^ N+7

;

; **** COMMAND DATA FOR RECALIBRATE ****

;

RECALCOM DEFB 2 ; 2 Parameters

DEFB 7 ; Command Code For RECALIBRATE

DEFB 0 ; Which Drive

;

; **** COMMAND CODE FOR DDFDC WRITE SECTOR ****

;

writcomd ; Write Command Data

DEFB 9 ; 9 Parameters

DEFB #45 ; WRITE DATA Command Alter #49 Del. Dta

DEFB 0 ; Drive

DEFB 0 ; Track

DEFB 0 ; Head Number

DEFB 0 ; Sector To Read

DEFB 0 ; Number Of Data Bytes Per Sector

DEFB 0 ; End Of Track

DEFB 0 ; Gap #3 - Generally #2a

DEFB #ff ; Data Length - Sect Size < 256

;

; **** WRITE DATA RESULTANT BYTES FROM RESULT PHASE ****

;

writcomr ; Write Command Result Table

DEFB 0 ; Status Register 0

DEFB 0 ; Status Register 1

DEFB 0 ; Status Register 2

DEFB 0 ; Track Number

DEFB 0 ; Head Number

DEFB 0 ; Sector Number

DEFB 0 ; Sector Size

;

; **** COMMAND DATA FOR READ SECTOR ****

;

readcomd ; Read Command Data

DEFB 9 ; 9 Parameters

DEFB #46 ; READ DATA Command Alter To #4C Del.

DEFB 0 ; Drive

DEFB 0 ; Track

DEFB 0 ; Head Number

DEFB 0 ; Sector To Read

DEFB 0 ; Number Of Data Bytes Per Sector

DEFB 0 ; End Of Track

DEFB 0 ; Gap #3 - Generally #2a

DEFB #ff ; Data Length - Sect Size < 256

;

; **** READ DATA RESULTANT BYTES FROM RESULT PHASE ****

;

readcomr ; Read Command Result Table

DEFB 0 ; Status Register 0

DEFB 0 ; Status Register 1

DEFB 0 ; Status Register 2

DEFB 0 ; Track Number

DEFB 0 ; Head Number

DEFB 0 ; Sector Number

DEFB 0 ; Sector Size

;

; **** Header Buffer For Formatting A Disk ****

;

fo ; Format Disk

DEFB 0,0,#c1,2 ; Data For Sector Numbers To Format

DEFB 0,0,#c6,2 ; In This Case DATA Format

DEFB 0,0,#c2,2

DEFB 0,0,#c7,2

DEFB 0,0,#c3,2

DEFB 0,0,#c8,2

DEFB 0,0,#c4,2

DEFB 0,0,#c9,2

DEFB 0,0,#c5,2

;

dd DEFS 20,0

Appendix

The following contains info of relevant registers, remember the Most Significant Bit (Bit 7) is to the Left, the Least Significant Bit (Bit 0) is to the right.

Status Register 0 (ST0)

| BIT | Name | info |

|---|---|---|

| 0 | US0 – Unit Select 0 | Drive A or B (If Bit Set). |

| 1 | US1 – Unit Select 1 | Drive C or D (If Bit Set) – Not used on the Amstrad CPC. |

| 2 | HD – Head Address | Flag to indicate that state of the Head at Interrupt. |

| 3 | NR – Not Ready | Indicates the Drive isn’t ready to send or receive commands/data if you try to send/receive data. |

| 4 | EC – Equipment Check | Set if the Drive is unable to recalibrate or there’s an error with the drive unit. |

| 5 | SE – Seek End | Set when the SEEK Command has physically completed the move to Track X |

| 6 7 | IC – Interrupt Code | 6 = 0, 7 = 0 – Normal Termination of the Command 6 = 1, 7 = 0 – Abnormal Termination of the Command 6 = 0, 7 = 1 – Invalid Command Issued 6 = 1, 7 = 1 – Abnormal Termination during command as Ready State Signal Received. |

Status Register 1 (ST1)

| BIT | Name | Info |

|---|---|---|

| 0 | MA – Missing Address Mark | If the FDC can not find a valid IDAM before two revolutions of the disk (Index Pulsed). |

| 1 | Not Writeable | During a Write Operation, the Write Protect Signal was detected. |

| 2 | ND – No Data | If during a READ, WRITE or SCAN operation the Specified Sector could not be found. If during a READ ID command, the ID could not be read without an error. If during READ Diagnostic Command, the start sector could not be found. |

| 3 | Not Used | Always 0 |

| 4 | OR – Overrun | The Controller wasn’t serviced (Data sent or received) from software within a set time interval. |

| 5 | Data Error | CRC Failure in either the ID Field or the DATA |

| 6 | Not Used | Always 0 |

| 7 | EN – End of Cylinder | Set when trying to access a sector not on this track. |

Status Register 2

| BIT | Name | Info |

|---|---|---|

| 0 | MD – Missing Address Mark | Set if the FDC cannot find a Data Address Mark or Deleted Data Address Mark. |

| 1 | BC – Bad Cylinder | Related to the ND Bit in ST1, when the contents of the Cylinder ID Stored on the medium differs from the from data stored in the IDR. |

| 2 | SN – Scan Not Satisfied | During the SCAN command, if the Sector ID can not be found. |

| 3 | SH – Scan Equal Hit | If the Sector ID matched that of the SCAN Command, then this is set. |

| 4 | WC – Wrong Cylinder | Related to the ND Bit in ST1, when the contents of the Cylinder ID Stored on the medium differs from the from data stored in the IDR. |

| 5 | DD – Data Error in Data Field | CRC Error in the data read. |

| 6 | CM – Control Mark | Set during a Read Data or Scan Command, set if a sector contains a deleted data address mark. |

| 7 | Not Used | Always 0 |

Status Register 3 (ST3)

| BIT | Name | Info |

|---|---|---|

| 0 | US0 – Unit Select 0 | Status of the Unit Select 0 = A, 1 = B |

| 1 | US1 – Unit Select 1 | Status of the Unit Select 0 = C, 1 = D |

| 2 | HD – Head Address | Status of the Side Select (0 = Side A, 1 = Side B) |

| 3 | TS – Two Sided | Two Sided Drive Status? |

| 4 | T0 – Track Zero | Track Zero Detected |

| 5 | RY – Ready | The FDC Is Ready |

| 6 | WP – Write Protect | Write Protect Signal, 1 = WP |

| 7 | FT – Fault | Fault was detected. |

Little error here :

motoron

LD A,1

motorctl

LD BC,#7FAA ; FA7E should be better 🙂

OUT (C),A

RET

motoroff

XOR A

JR motorctl

LikeLiked by 1 person

Thank you, I’ve corrected it… Clearly I hadn’t had enough coffee when proof reading!

LikeLike

Thanks a lot. I was looking for such code at some point.

Note that patchrwd can be simplified, methinks :

patchrwd ; Patch Read Write Data

PUSH hl

PUSH af

LD (hl),e

INC hl

LD (hl),d

INC hl

LD (hl),e

INC hl

LD (hl),c

INC hl

LD a,(sectsize) ; Get Sector Size From XDPB

LD (hl),a ; Store It

INC hl ; Point To End Of Track

LD (hl),c ; Store Sector

INC hl ; Point To Gap Length

LD a,(gap3rw) ; A = Gap #3 For READ/WRITE

LD (hl),a ; Store It

INC hl ; Point To Data Length

LD a,(dataleng) ; A=Sector Length

LD (hl),a ; Store It

POP af

POP hl

RET

LikeLiked by 1 person